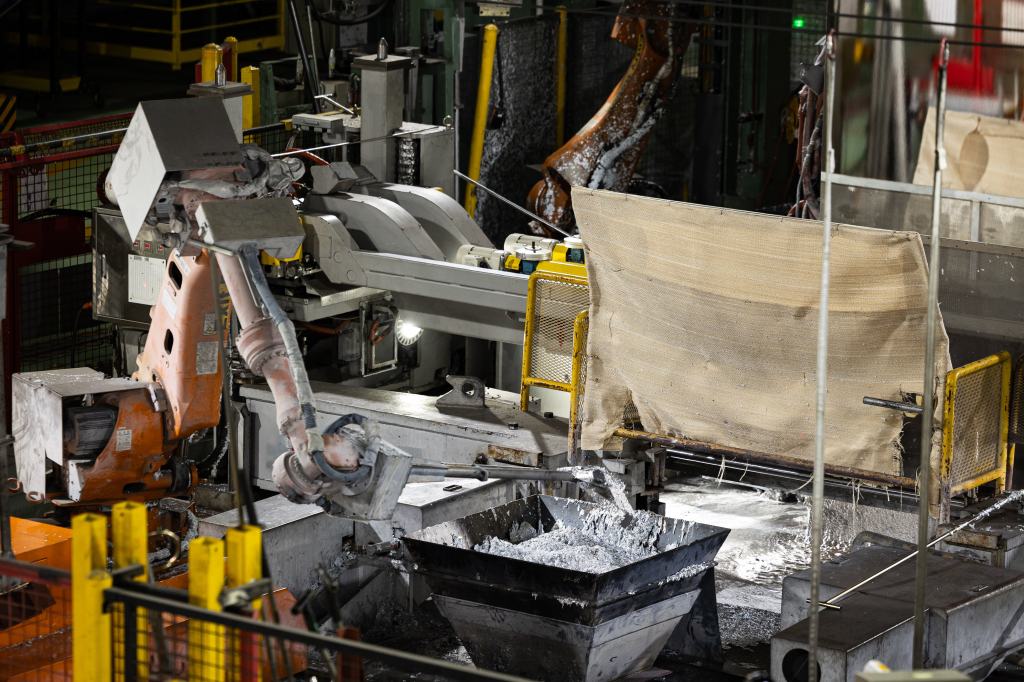

On the 6th, visiting the galvanizing plant at POSCO Gwangyang Steelworks, steel plates were immersed in a large tank of molten zinc at 600°C before emerging again. The thin steel sheets, as wide as 1.65 meters and with thickness ranging from 0.4 to 2.3 millimeters, become automotive-grade steel after this process, giving them a shiny, mirror-like finish.

What drew attention was the ‘AI robot arm’ mixing the bath using a shovel. When cameras above identified contaminants, the robot arm promptly eliminated floating impurities. This avoids significant flaws resulting from residue sticking to the steel surface.

In the past, employees wearing heat-resistant suits had to manually remove 30-kilogram portions of impurities using shovels. There were significant safety hazards, and the quality of work depended on individual expertise. Although robots were later introduced, detecting floating debris was still a human responsibility. Today, AI manages all aspects of the process.

The Gwangyang Steel Plant, which generates 21 million tons of steel each year, is experiencing a significant transformation powered by artificial intelligence. AI is being implemented across various stages, including the transportation of iron ore and coal, the steelmaking process—eliminating impurities from molten iron—and the galvanizing procedures. At present, 29 AI robot arms are removing zinc impurities to create highly reflective steel sheets.

◇Where humans perform 25 times, AI accomplishes it with a single click

The method of eliminating impurities by blowing oxygen into molten iron was previously a manual challenge, but AI has transformed it entirely. During the visit to the steel plant that day, pressing the ‘Start’ button on the control room screen caused the converter furnace holding high-temperature molten iron to tilt. For 1–2 minutes, impurities were poured out, after which the furnace returned to its initial position. AI calculated the best pouring volume and angle.

Previously, workers with many years of experience manually adjusted oxygen levels and pouring angles by pressing buttons 25 times, depending on their knowledge. Even small mistakes could result in molten iron at 1,600°C overflowing, causing serious accidents. Since 2018, the plant has gathered seven years of operational data to get ready for AI implementation. In 2019, it successfully automated ‘tapping’—the most difficult and dusty process—which sped up the widespread use of AI. A factory official stated, “The time before AI seems like the Joseon Dynasty now.” Currently, it is being used in one converter furnace, and expanding it to all three next year will enhance efficiency, saving 3.38 billion Korean won each year.

◇AI oversees 70-meter-tall conveyor belts

A ‘AI security guard’ is operating in the facility that transports raw materials such as iron ore and coal from the port to the factory. A soccer ball-sized ‘SmartWireBall’ travels along wires next to conveyor belts at a speed of 4 km/h, gathering acoustic, visual, and thermal data. It acts as a mobile CCTV system moving at a pace similar to a person walking.

With conveyor belts covering an area of 22 square kilometers (approximately 6.66 million pyeong) throughout the facility, manual checks are practically unfeasible. The entire belt system measures 335 kilometers in length—comparable to the direct distance between Seoul and Busan. Certain parts rise up to 70 meters high, equivalent to about 26 floors.

A representative from the site stated, “When coal catches fire on its own, people typically only become aware when smoke appears, but the SmartWireBall identifies temperature changes immediately, identifying them as warning signs.” They further mentioned, “It has successfully avoided incidents.”

Leave a comment